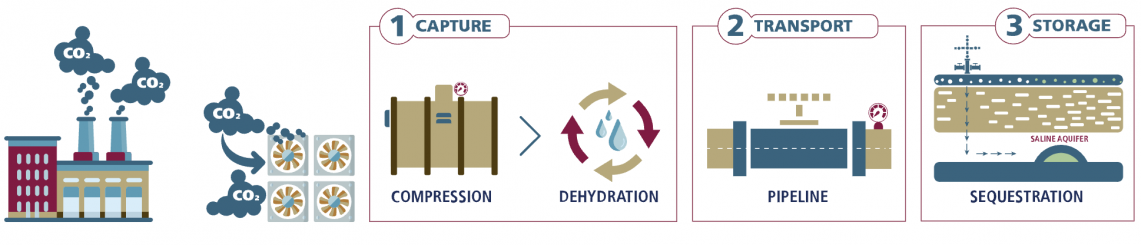

Carbon capture and storage (CCS), also known as carbon capture and sequestration, helps industrial producers meet environmental requirements in a cost-effective and responsible manner by capturing carbon dioxide (CO2), transporting it, and storing it safely and permanently deep underground.

Live Oak CCS Hub representatives are reaching out to landowners in this area about acquiring access to pore space on their property. Pore space rights are similar to mineral rights, but we would acquire the rights to store CO2 rather than remove it.

CO2 is captured at the point of emission, such as ethanol plants, agribusiness, natural gas processing plants, steel processing and other facilities, or through direct air capture, rather than being released into the atmosphere. The CO2 is then processed and compressed into a liquid.

The captured CO2 is liquefied and transported. A high-strength carbon steel pipeline system safely delivers the liquefied CO2 to a storage site. After storage, the CO2 then naturally mineralizes and dissolves over time.

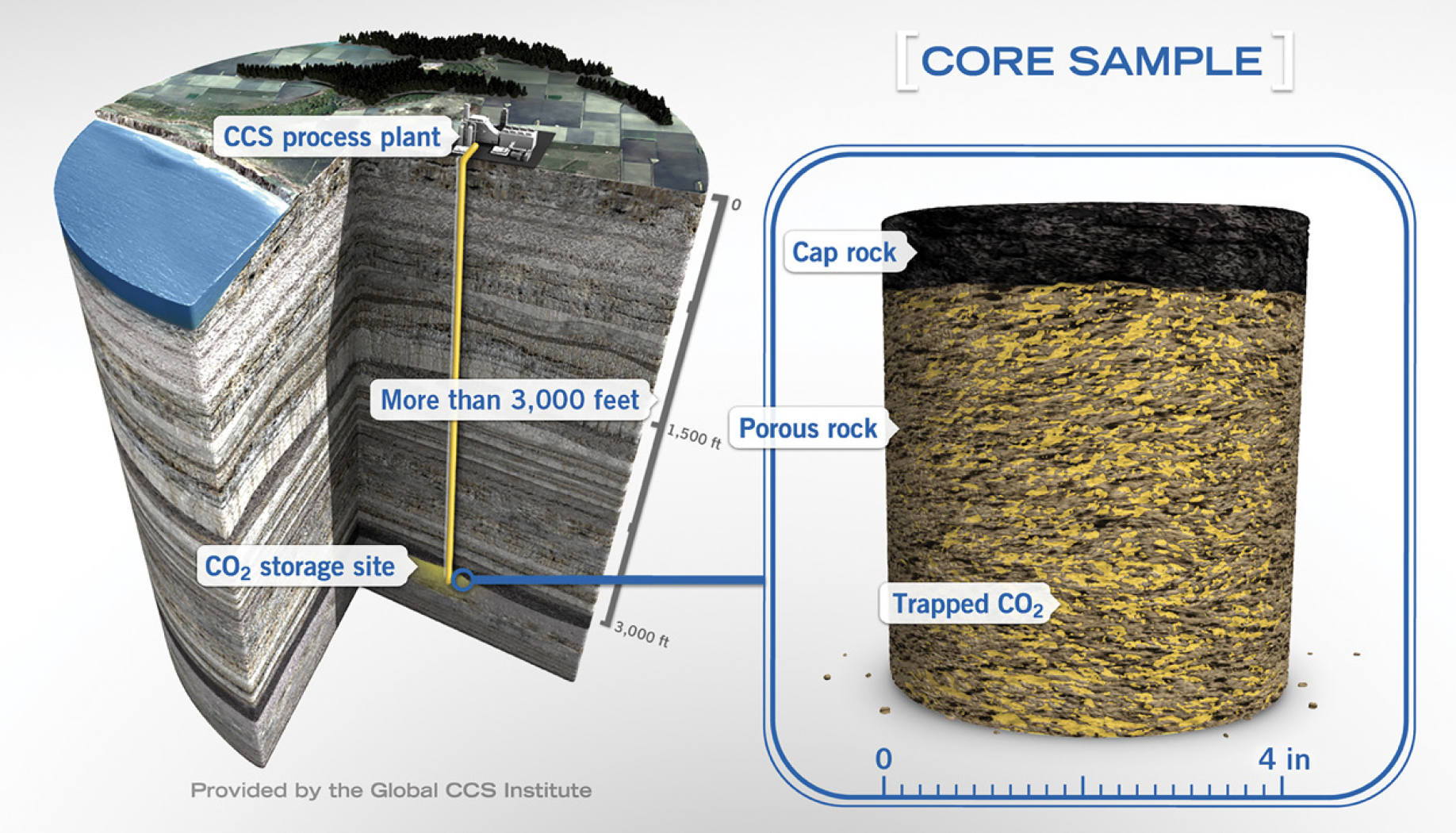

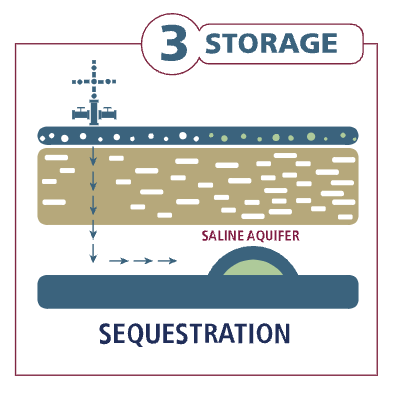

The liquefied CO2 is injected deep underground, where it is stored in porous rock and sealed beneath a thick layer of impermeable cap rock. The CO2 then naturally mineralizes and dissolves over time.

The project team reviews the area to ensure it meets criteria for geologic storage of CO2. Storage areas are pinpointed using maps, published studies, rock samples and seismic imaging data. |

The project team seeks to engage in agreements with landowners for injection well sites, monitoring well sites and underground pore space rights. Our land agents work with landowners to go over agreements in detail and address any questions. |

Once enough agreements are signed, a characterization well may be drilled if required to confirm the geology of the area. Seismology studies are also performed. |

Various engineering and environmental studies are performed, and participating landowners are notified in advance of any study work on their land. These studies analyze local geology, wetland areas and soil characteristics to ensure injection well placement is as safe, minimally invasive and efficient as possible. |

The project applies for a U.S. Environmental Protection Agency (EPA) Class VI injection well permit, which must meet rigorous standards to protect underground sources of drinking water. The project also applies for applicable state permits and local zoning requirements. |

The Live Oak CCS team secures a commitment from an emissions customer(s) in need of CO2 storage to help assure the overall economic viability of the project. |

The Live Oak CCS team provides education to the local community about CCS and works with local leaders to maximize the project’s economic benefits. |

An engineering, procurement and construction contractor is hired to drill the injection well and connect a pipeline from the underground storage area to emissions customers. We aim to source qualified, local labor and local materials when possible. |

The storage site is monitored 24/7 during the operations period. An on-site operations team of 2-3 people maintains the site for the life of the project. |

Once the storage space is full, the injection wells are plugged and monitored for a period of time specified by the EPA. The liquified CO2 underground will continue to mineralize and dissolve over time. |

The project team reviews the area to ensure it meets criteria for geologic storage of CO2. Storage areas are pinpointed using maps, published studies, rock samples and seismic imaging data. |

The project team seeks to engage in agreements with landowners for injection well sites, monitoring well sites and underground pore space rights. Our land agents work with landowners to go over agreements in detail and address any questions. |

Once enough agreements are signed, a characterization well may be drilled if required to confirm the geology of the area. Seismology studies are also performed. |

Various engineering and environmental studies are performed, and participating landowners are notified in advance of any study work on their land. These studies analyze local geology, wetland areas and soil characteristics to ensure injection well placement is as safe, minimally invasive and efficient as possible. |

The project applies for a U.S. Environmental Protection Agency (EPA) Class VI injection well permit, which must meet rigorous standards to protect underground sources of drinking water. The project also applies for applicable state permits and local zoning requirements. |

The Live Oak CCS team secures a commitment from an emissions customer(s) in need of CO2 storage to help assure the overall economic viability of the project. |

The Live Oak CCS team provides education to the local community about CCS and works with local leaders to maximize the project’s economic benefits. |

An engineering, procurement and construction contractor is hired to drill the injection well and connect a pipeline from the underground storage area to emissions customers. We aim to source qualified, local labor and local materials when possible. |

The storage site is monitored 24/7 during the operations period. An on-site operations team of 2-3 people maintains the site for the life of the project. |

Once the storage space is full, the injection wells are plugged and monitored for a period of time specified by the EPA. The liquified CO2 underground will continue to mineralize and dissolve over time. |

We know your land is your livelihood, whether you use it for farming, ranching, recreation, leasing or other purposes. We aim to be a good steward of this land, support its long-term preservation and provide an added source of income for your family over the next 20+ years.

Other than a few carefully sited wells above ground, the storage area is safely located deep underground. You can continue using the land’s surface for other purposes.

A carbon capture and storage (CCS) project allows landowners to create value from an unused part of the land’s geology deep beneath the surface. Your family can receive payments from the pore space rights for decades.

Costs associated with the development, construction and operation of the storage field are paid for by the company.

© 2023 Live Oak CCS Hub. All rights reserved.